Downstream

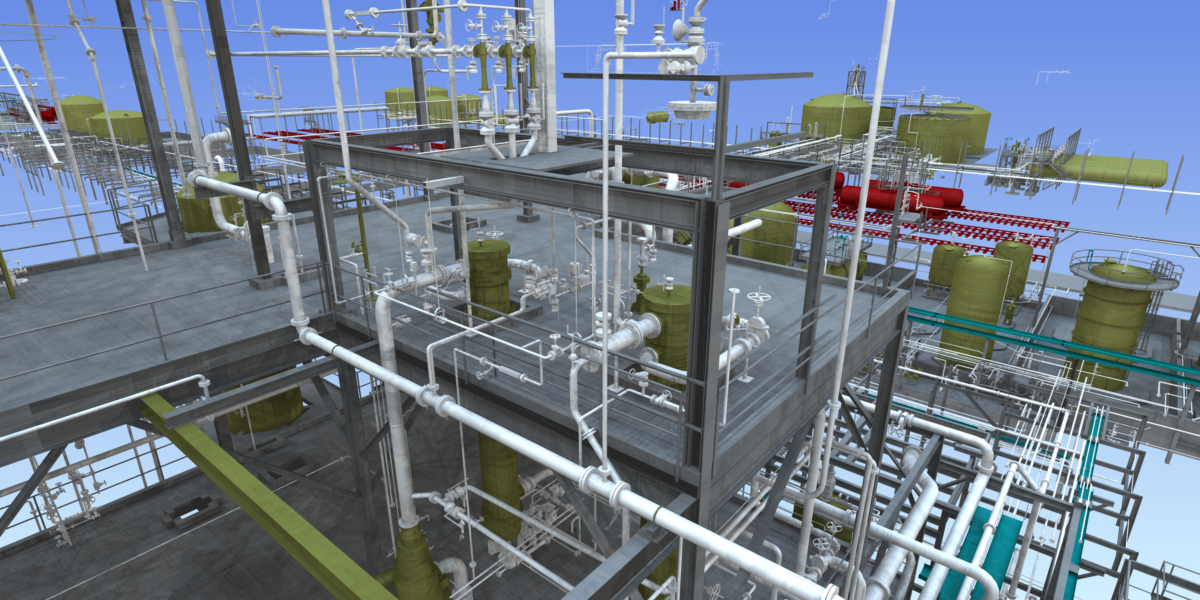

For each Downstream project, our goal is to build plant capacity so our clients can realize their production goals and meet their customers’ expectations.

For each Downstream project, our goal is to build plant capacity so our clients can realize their production goals and meet their customers’ expectations.

Closed Vent System for Emissions Control – EDG staff managed the design and installation of a plant-wide closed-vent system for reducing emissions of hydrocarbon and hazardous air pollutants at a rubber polymer plant to comply with air quality standards.

Click the links to find out more: About EDG, Inc. // EDG, Inc. Projects // EDG, Inc. Industries We Serve // EDG, Inc. Services // EDG Unifying Principles

Follow EDG on our social sites: LinkedIn: @EDG // Facebook: @EDGInc // Twitter: @EDGInc

Follow EDG on our social sites: LinkedIn: @EDG // Facebook: @EDGInc // Twitter: @EDGInc