EDG Consulting Engineers Private Limited (EDGPL), also referred to as EDG India, supports various EDG Offices around the globe. The local Indian market, being driven largely by Indian National Oil Companies, is driven by past references and lowest prices. EDGPL focuses on its capabilities built on serving other EDG offices as well as additional territories in Malaysia and Nigeria.

EDG Pune (EDGPL) Capabilities

Mechanical and Packaging

Pressure Vessels

- Coded vessels designed to ASME Section VIII Div. I and II

- Pressure vessels designed to PED Codes

Heat Exchangers

- Air cooled heat exchangers designed using HTRI

- Shell and tube type heat exchangers to TEMA

Modular Designs

- Compressor packages, pump packages, tankages

Finite Element Analysis

- Using ANSYS, Solidworks and Fluent

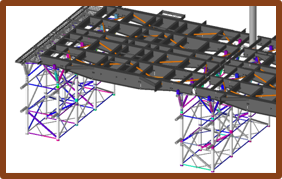

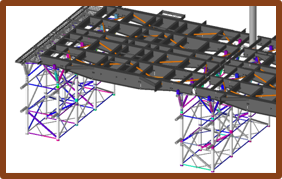

Civil / Structural Engineering

Structural Analysis / Finite Element Analysis

- SACS, STADD-Pro, ANSYS, Solidworks Simulation, and Fluent

Design and Drafting

- PDMS- E3D, AutoCAD, Bentley, Autoplant, Autodesk Plant 3D

Process / Facilities Engineering

Process Modeling

- Development of Design Basis

- Process Flow Diagram

- P&IDs

Hydraulic Studies

- Flow Modeling and Analysis

HAZOP and Safety Studies

- Providing HAZOP Chairman and Secretary

- Safety Studies and Review

Electrical and Instrumentation

Preparation of Electrical and Instrumentation Discipline Drawings and Documents

- Electrical equipment and instruments specification documents and drawings

- Development of load lists

- Assist in P&ID review and development

- Field instruments layout and installation support

- Routing drawings for cables and trays

- Attending Fat and Sat

- Review of vendor data and drawings

- Inter-discipline interface

Piping Engineering

Piping Specifications Development

Development of Design Basis

- Optimization of pipe routings

- Supporting – Standardization of supports

- Optimum usage of space

Piping Stress Analysis

- Pipe stress calculations and supporting

- Optimize expansion loops

- Prepare and finalize client reports

Design and Drafting

- Review of plot and plan layout strategy

- Preparation of equipment layout

- PDMS administration an development of CATS and specs

- PDMS modeling (equipment, piping, structural, E&I)

- Clash check

- Implementing safety in design

- Preparation of piping layouts, extraction of isometrics and support drawings

- Extraction of MTOs

- All 2D drafting work utilizing AutoCAD/Microstation

Drafting Software in Use

- PDMS 11.6 and 12 / E3D (through PDMS global)

- AutoCAD

- Autodesk Plant 3D

- Bentley Autoplant

- Smart Plant P&ID (licenses leased as required)

- Navisworks

Engineering Software in Use

- Caesar II for piping stress analysis

- HTRi for heat exchanger design (FIN-FAN / S&T)

- PV Elite

- Solidworks Simulation

- STADD-PRO

- Tekla (through Vadodara/Bangalore office)

- SACS (through Vadodara office)

- ANSYS (through FE Solutions)

- HYSYS (leased per requirement)

- SPPID (leased per requirement)

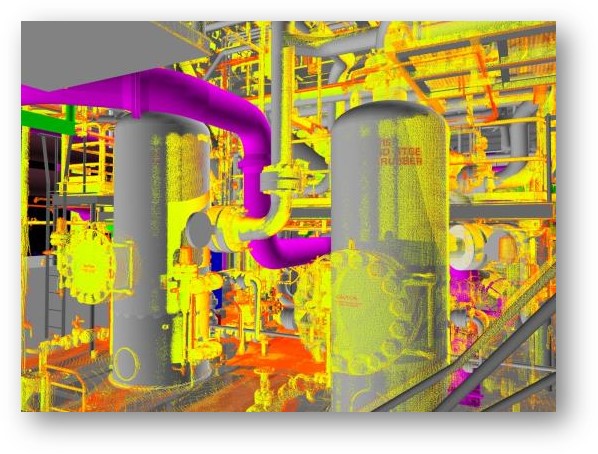

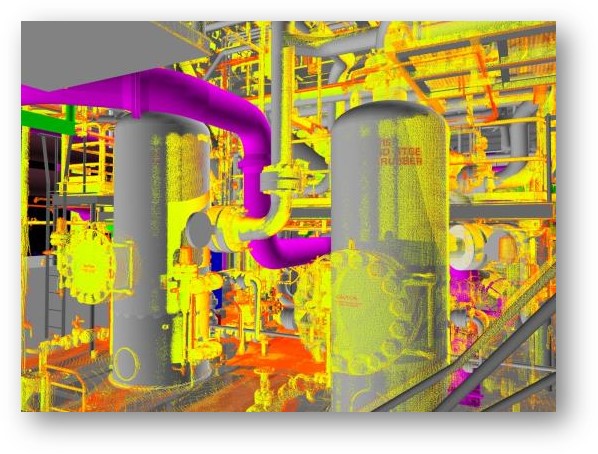

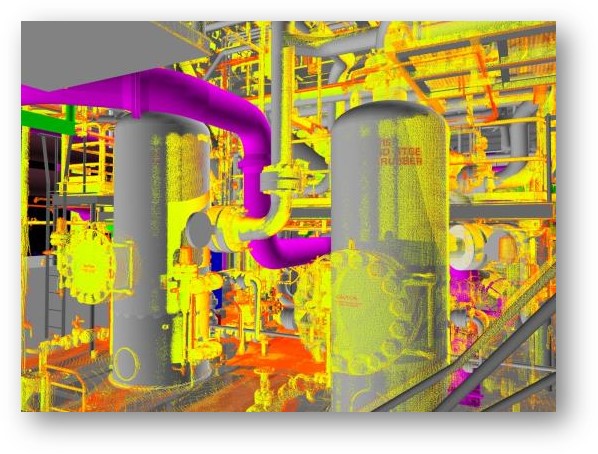

As Building

- Based on provided point clout data, full PDMS model developed and delivered to present “as is” state of site

- Improved safety features incorporated

- Future maintainability and ease of operation defined

EDG Pune Milestones

- 2009: Support major client project and other Angola projects

- 2010: Support setting up Singapore office and providing process, project engineering, design and drafting as well as piping stress analysis support to the Singapore team and client projects

- 2010: Set up Abu Dhabi office and winning first brownfield project from major client

- 2011: Support client’s New Guinea project

- 2011: Major client Bangladesh Project

- 2012 – 2014: GVLA and MSP projects

- 2020: Support various offices and winning structural support work for FEED through major client in Nigeria

- 2021: Adding alliances in field of electrical and process licensing for bio-diesel and methanol midstream process plants

View our Projects page for brief project summaries.

Contact Jaggi Kaul for more information: