Gulf of Mexico Field Upgrade

The Gulf of Mexico Field Upgrade was an effort aimed at ensuring surface facilities at the Gulf of Mexico Main Pass 299/144 asset are available to capture remaining economic reserves.

The Gulf of Mexico Field Upgrade was an effort aimed at ensuring surface facilities at the Gulf of Mexico Main Pass 299/144 asset are available to capture remaining economic reserves.

Aging infrastructure, facility condition, and escalating OPEX were the key issues we needed to address.

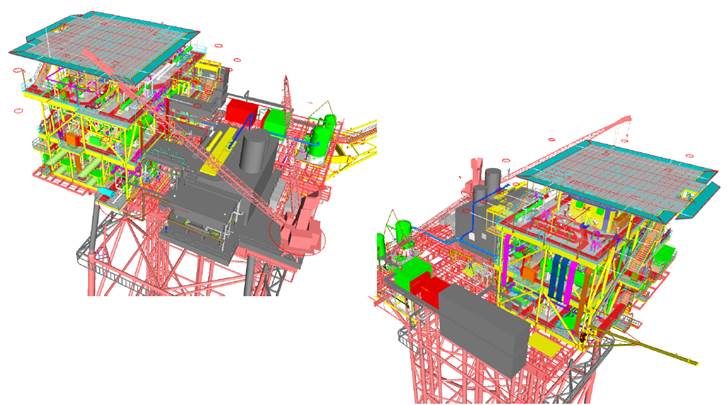

In this instance, the existing jacket and deck structure were deemed viable for the forecasted remaining field life. However, the process and utility infrastructures were deficient. Thus, a fully integrated bulk oil and water-treating production module was designed to maximize onshore fabrication and pre-commissioning efforts—while also reducing offshore installation durations and risks.

EDG, Inc. assembled a multi-discipline team including members from Project Management, Facilities/Process/Electrical/Structural Engineering, Cost Estimating, Procurement, Document Control, and Project Controls. The team conducted IPM modeling (PROSPER and GAP software), developed and analyzed alternatives, developed cost estimates and schedules, and performed FEED and DE.

The resulting Production Module was three (3) levels—plus a Helideck—and weighed approximately 840 tons. It included bulks separators, oil dehydrator, induced gas flotation unit, heat exchangers, vapor recovery compression, sales oil metering, multiple pump packages, waste heat recovery, turbine generators, MCC building, fuel gas conditioning, instrument/utility air system, firewater hose reels, rotatable atmospheric vent boom, and local control panels.